Polycab - Rubber Cables

Deekay Electricals are authorized distributor and dealer for Polycab Cables. Polycab Rubber Cables are used for trailing and flexible supply leads in either single or multi core versions. All cables used in electronics are insulated with materials like plastic or rubber.

Provide us your requirments. Our Experts will get in touch with you shortly.

- Conductor: Class 5 annealed tin electrolytic grade copper conductor as per IS 8130

- Insulation : Special EPR compound equivalent to or better than IE2 as per IS 6380

- Outer sheath: Special elastomeric compound based on PCP, CSP, NBR – PVC,CPE equivalent to or better than SE4, HOFR as per IS 6380.

- Rated Voltage: 1 .1 KV

- AC Test Voltage : 3.0 KV

- Fixed Installation : – 40 Deg C to+ 90 Deg C

- In Operation : – 25 Deg C to+ 90 Deg C

Excellent flexibility, Smooth finish, Enhanced resistance to Ozone, Oxygen, Heat, Solvent, Chemicals and Fire.

| Nominal Cross Section Sq.mm | Nominal Thicknessof Insulation mm | Max Cond. DC Resistance @ 20 Deg C Ohms/Km | Max Temp. of the Cond. During Operation Deg C | Max Temp. of the Cond. During Shot Circuit Deg C | Overall Diameter | |||

|---|---|---|---|---|---|---|---|---|

| 1 Core | 2 Core | 3 Core | 4 Core | |||||

| 4 | 1.0 | 5.09 | 90 | 250 | 7.8 | 13.2 | 13.5 | 15.4 |

| 6 | 1.0 | 3.39 | 90 | 250 | 10.0 | 17.0 | 18.0 | 20.4 |

| 10 | 1.2 | 1.95 | 90 | 250 | 11.8 | 20.6 | 22.0 | 24.2 |

| 16 | 1.2 | 1.24 | 90 | 250 | 13.6 | 24.0 | 25.8 | 28.4 |

| 25 | 1.4 | 0.795 | 90 | 250 | 15.7 | 29.2 | 31.4 | 34.2 |

| 35 | 1.4 | 0.565 | 90 | 250 | 17.4 | 32.2 | 34.4 | 37.6 |

| 50 | 1.6 | 0.393 | 90 | 250 | 20.2 | 37.2 | 39.8 | 43.6 |

| 70 | 1.6 | 0.277 | 90 | 250 | 22.5 | 41.2 | 44.2 | 48.6 |

| 95 | 1.8 | 0.21 | 90 | 250 | 25.4 | 46.6 | 50.2 | 55.2 |

| 120 | 1.8 | 0.164 | 90 | 250 | 27.6 | 50.6 | 54.2 | 60.0 |

| 150 | 2.0 | 0.132 | 90 | 250 | 30.4 | 55.6 | 59.6 | 66.0 |

| 185 | 2.2 | 0.108 | 90 | 250 | 33.4 | 60.6 | 65.2 | 72.5 |

| 240 | 2.4 | 0.0817 | 90 | 250 | 36.8 | 67.6 | 72.8 | 81.0 |

| 300 | 2.6 | 0.0654 | 90 | 250 | 40.0 | 74.6 | 80.4 | 89.4 |

| 400 | 2.8 | 0.0495 | 90 | 250 | 45.0 | 84.0 | 90.6 | 100.8 |

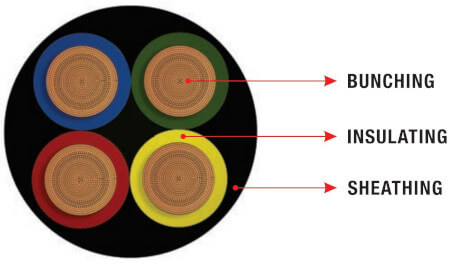

- Conductor: Class 5 annealed tin electrolytic grade copper conductor as per IS 8130.

- Insulation: Special EPR compound equivalent to or better than IE2 as per IS 6380.

- Outer sheath: Special elastomeric compound based on PCP, CSP, NBR-PVC,CPE equivalent to or better than SE4, HOFR as per IS 6380

- Rated Voltage : 1 .1 KV

- AC Test Voltage : 3.0 KV

- Fixed Installation : – 40 Deg C to+ 90 Deg C

- In Operation : – 25 Deg C to+ 90 Deg C

Excellent flexibility, Smooth finish, Enhanced resistance to Ozone, Oxygen, Heat, Solvent, Chemicals and Fire.

| Nominal Cross Section Sq.mm | CORE Nos | Nominal Thickness of Insulation mm | Max Cond. DC Resistance @20 Deg C Ohms/Km | Max Temp. of the Cond. During Operation Deg C | Max Temp. of Cond. During Shot Circuit Deg C | Overall Diameter mm |

|---|---|---|---|---|---|---|

| 1.5 | 7 | 1.0 | 13.7 | 90 | 250 | 14.6 |

| 1.5 | 12 | 1.0 | 13.7 | 90 | 250 | 21.0 |

| 1.5 | 24 | 1.0 | 13.7 | 90 | 250 | 29.0 |

| 2.5 | 7 | 1.0 | 8.21 | 90 | 250 | 16.0 |

| 2.5 | 12 | 1.0 | 8.21 | 90 | 250 | 23.0 |

| 2.5 | 24 | 1.0 | 5.09 | 90 | 250 | 31.5 |

2 Core upto 36.

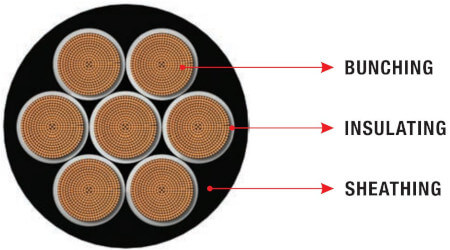

- Conductor: Class 5 annealed tin electrolytic grade copper conductor as per IS 8130.

- Insulation: Special EPR compound equivalent to or better than IE2 as per IS 6380.

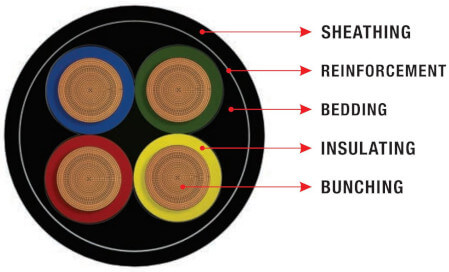

- Bedding: Special elastomeric compound conforming to SE3 I SE4 as per IS 6380.

- Reinforcement: Anti-torsional reinforcement between bedding and outer sheath.

- Outer sheath: Special elastomeric compound based on PCP, CSP, NBR-PVC,CPE equivalent to or better than SE4, HOFR as per IS 6380.

- Rated Voltage 1.1 KV

- AC Test Voltage : 3.0 KV

Excellent flexibility, Smooth finish, Enhanced resistance to Ozone, Oxygen, Heat, Solvent, Chemicals and Fire.

Reeling & Unreeling application in dry, damp & wet locations as well as outdoors. As universal reeling cables for hoisting, transportation & handling equipment with heavy mechanical stresses, flexible wind energy cable.

Single core upto 400 Sq.mm, Multicore upto 240 Sq.mm, Control core 1.5 Sq.mm to 2.5 Sq.mm upto 36 core.

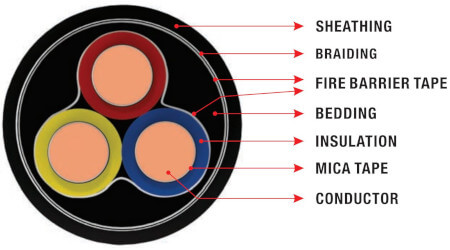

- Conductor: Class 1 or 2 annealed tin or plain electrolytic grade copper conductor as per IS 8130.

- Glass mica tape: Special glass mica tape suitable for 750°C or 950°C.

- Insulation: Special EPA compound equivalent to or better than IE2 as per IS 6380

- Bedding : Special Zero halogen elastomeric compound.

- Fire barrier tape: High temperature resistance glass fibre tape

- Braiding: Magnetic or non-magnetic metallic wire braiding.

- Outer sheath: Special zero-halogen LSF (Low smoke & fume) elastomeric compound.

- Circuit intrigity test at 750°C or 950"C confirming to IEC 60331

- Smoke density test conforming to AST MD 2843 or IEC 61034

- Vertical flame spread test confirming to IEC 60332

- Halogen acid gas test conforming to IEC-60754-1

- Rated Voltage : 1 .1 KV

- AC Test Voltage : 3.0 KV

Single core upto 630 Sq.mm, Multicore 2.5 Sq.mm to 240 sq mm.