Deekay Electricals are authorized distributor and dealer for Polycab Solar Cables. Our solar DC Cables are TUV approved as per EN 50618 standard. Typically, 4sq.mm and 6sq.mm sizes are used to connect the output of solar photovoltaic (“PV") panel to the array junction.

Provide us your requirments. Our Experts will get in touch with you shortly.

These cables are designed for connecting photovoltaic power supply systems. These cables can be used indoor & outdoor for flexible and fixed installations with high mechanical strength in extreme weather conditions.

2 Pfg 1169/08.2007.

- Rated Voltage: 0.6/1 kV AC

- Rated DC Voltage: 1.5 kV

- Maximum Permitted DC Voltage: 1.8 kV (conductor/conductor, non earthed system, circuit not under load)

- Maximum Permitted AC Voltage: 0.7/1.2 kV

- Working Voltage: DC 1000 V

- Insulation Resistance: 1000M Q – km

- Spark Test: 6000 Vac (8400 Vdc)

- Voltage Withstand: 6500 V as per EN50395 for 5 min

- Ampacity: According to requirements for cables for PV systems

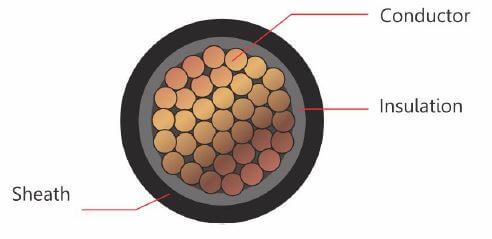

- Conductor : Electrolytic Multi Stranded tinned copper conductor flexible as per IEC 60228 Class 5.

- Insulation : Crosslinked Halogen Free & Flame Retardant Insulation

- Sheath : Sheath Crosslinked Halogen Free & Flame Retardant Sheath in Black/Blue/Red Colour

Note : Insulation thickness, Sheath thickness and Overall Dimensions given in this table are nominal values. The strand diameter is nominal. However, Construction of the conductor is designed to satisfy the requirement of conductor resistance as per IS 8130 :1984.

- Ambient Temperature: -40°C ~ +90°C

- Maximum Temperature at Conductor: 120°C (20000h)

- Short Circuit Temperature: 200°C (at conductor max. 5sec)

- Thermal Endurance Test: According to EN 60216-2 (temperature index +120°C)

- High Temperature Pressure: Test according to EN 60811-3-1

- Damp – Heat Test: According to EN 60068-2-78 1000 hrs at 90°C with 85% humidity

- Minimum Bending Radius: 5 x OD (fixed), 15 x OD (occasional flexing)

- Dynamic Penetration: According to requirement of Cables for PV systems 2 Pfg 1169/08.2007 Annex F

- Notch Propagation: According to 2 Pfg 1169/08.2007 Annex G

- Tensile Strength: 6.5 N/mm2 for insulation and 8 N/mm2 for sheathing – according to EN60811

- Elongation of Insulation and sheathing: 125% – according to EN60811

- Anticipated Period of Use: 25 years

- Shrinkage: 2% at 120°C according to EN60811-1-3

The cables are RoHS (Restriction of certain Hazardous Substances) compaliant as per EU Directives 2002/95/EC

- Mineral Oil Resistance: according to EN 60811-2-1

- Ozone Resistance: according to EN 50396 part 8.1.3 Method B

- Weathering-UV Resistance: according to HD 605/A1 or DIN 53367

- Ammonia resistant: 30 days in saturated ammonia atmosphere (internal testing)

- Very good resistance to oil and chemicals

- High wear and robust, abrasion resistant

- Acid & Alkaline Resistance: According to EN 60811-2-1 (Oxal acid and sodium hydroxide)

- Flame retardant according to IEC 60332-1-2

- Low smoke emission < 20% as per ASTM D-2843

- Halogen free according to EN 50267-2-1/-2, IEC 60754-2

- Acid gas emission not more than 0.5% as per IEC 60754-1 pH minimum 4.3 as per IEC 60754-2 conductivity maximum 10 as per IEC 60754-2

- Toxicity according to EN 50305, ITC- index < 3

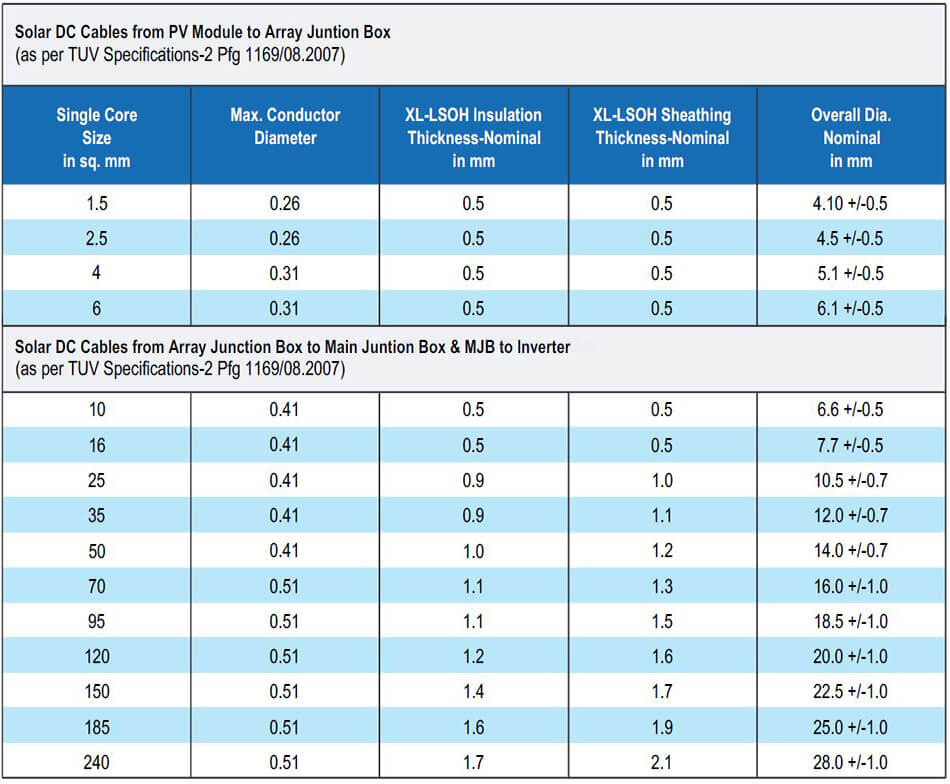

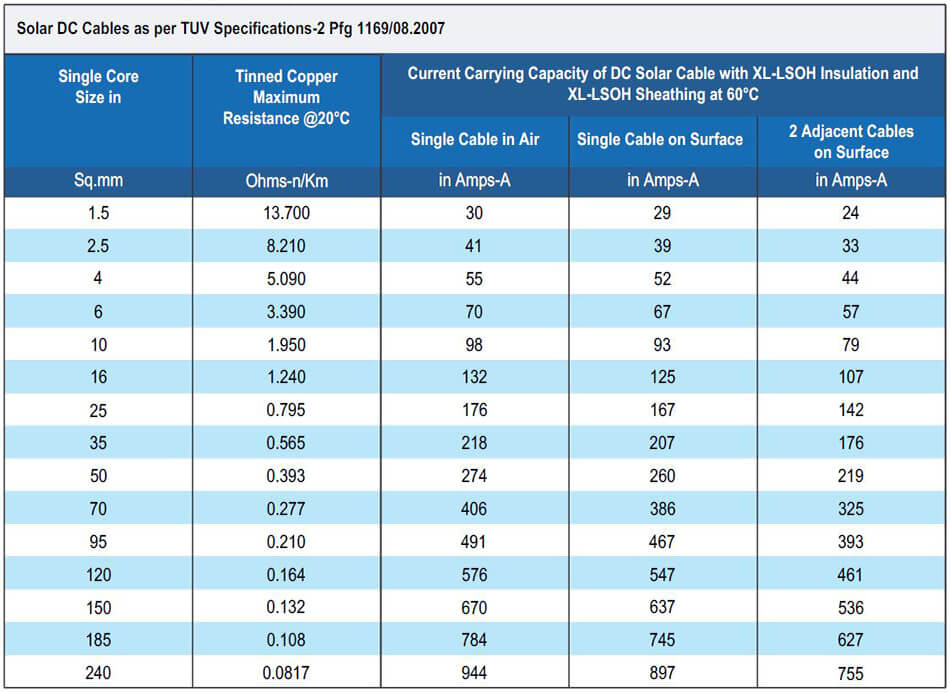

As per TUV Rheinland specification: 2 Pfg 1169/08.2007.

These cables though not exposed to direct sunlight are throughout the day time exposed to diffused/indirect sunlight and atmospheric temperatures in open air.

DC Solar Cables are Single core Copper cables each for +ve and -ve. They are insulated and sheathed with Cross Linkable LSOH which has UV as well as Ozone protection properties. These cables confirm to TUV specificationst.

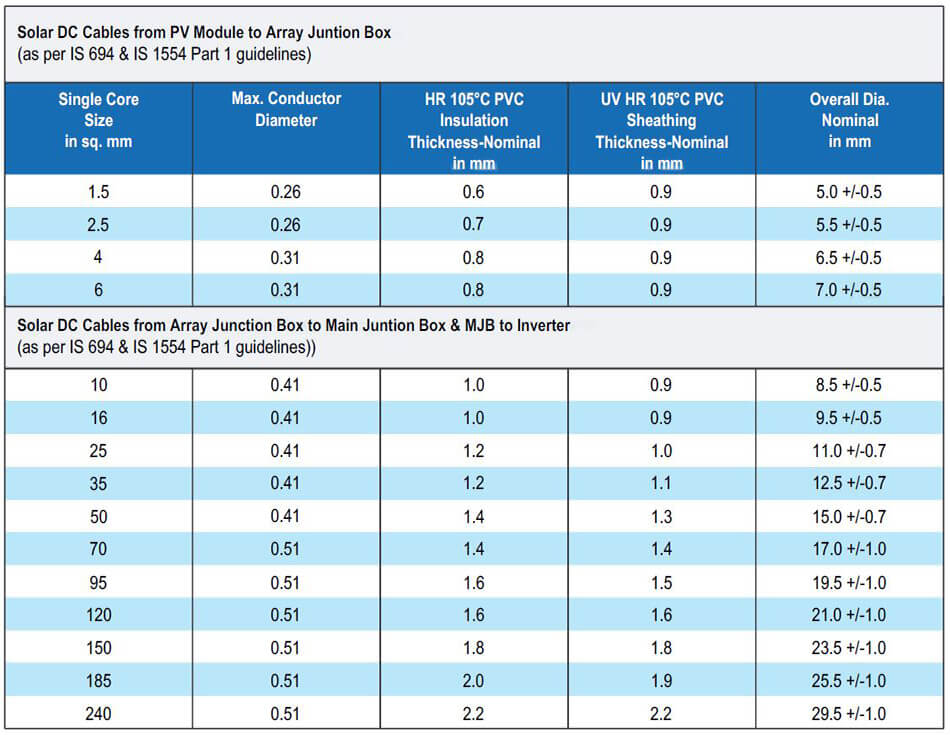

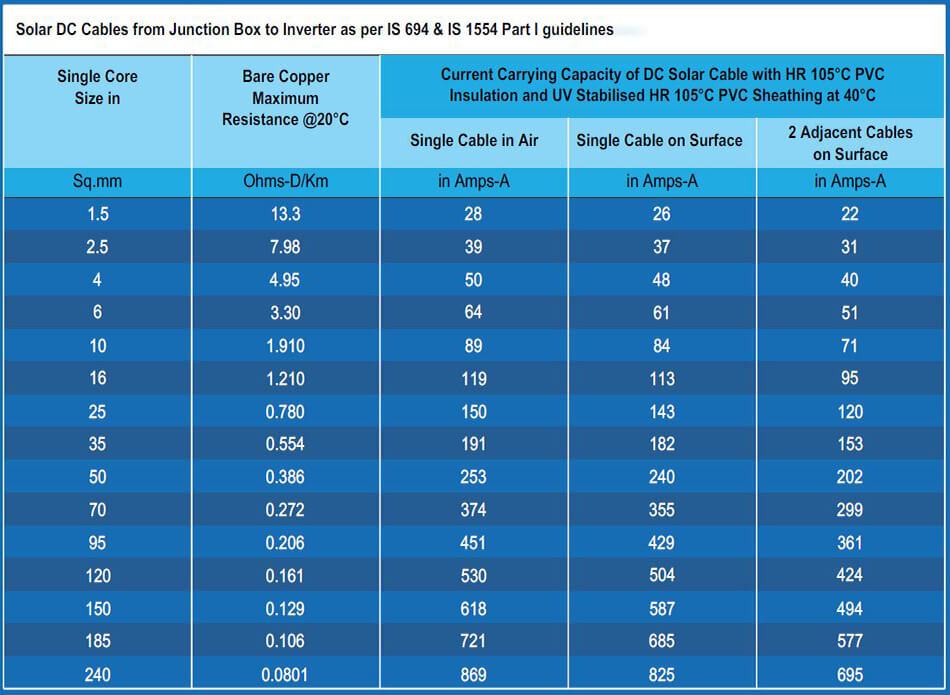

DC Solar Cables are Single core Copper cables each for +ve and -ve. They are insulated with HR 105°C PVC compound and sheathed with UV stabilized HR 105°C PVC compound.

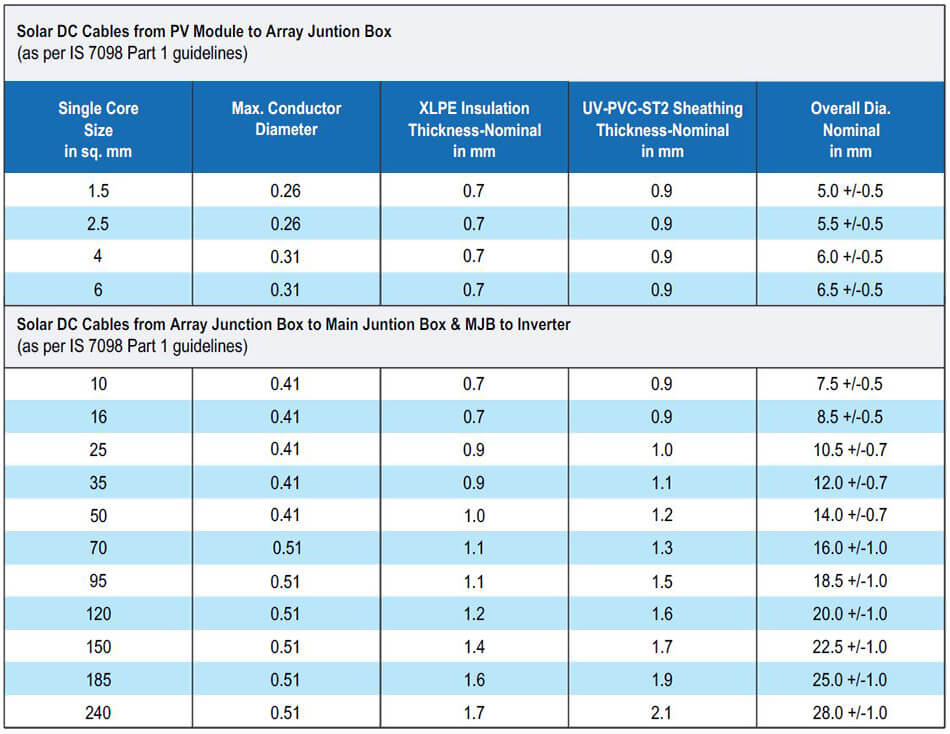

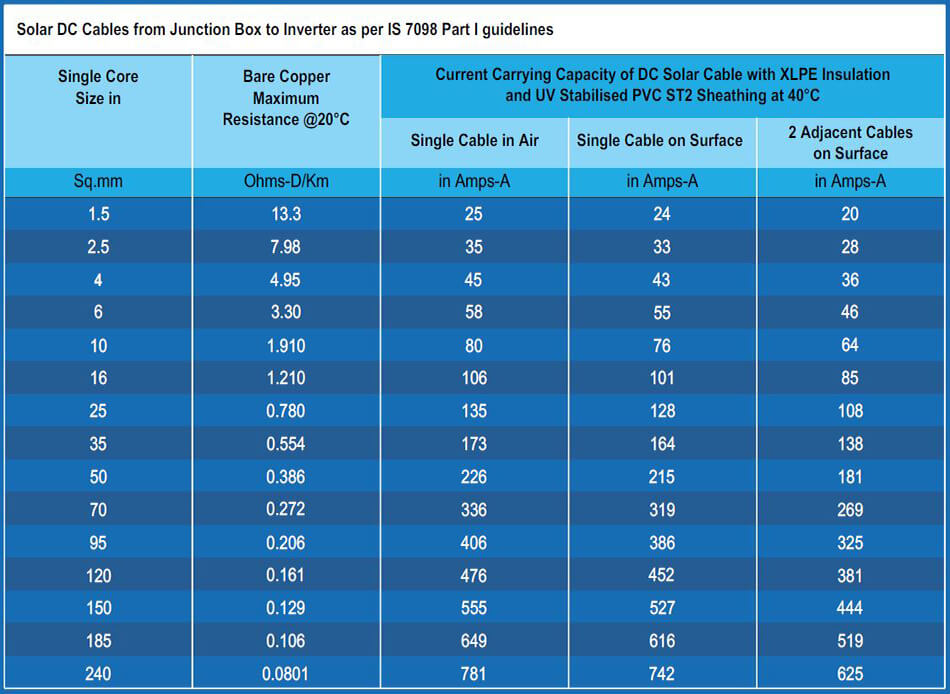

DC Solar Cables are Single core Copper cables each for +ve and -ve. They are insulated with XLPE compound and and sheathed with UV stabilized PVC ST2 compound.

These Solar DC cables which are not exposed to sunlight and are always routed through PVC Pipes which are laid underground. Choice of cables can be done from any one of the options given. Generally Option 3 is chosen for this route.

The Three Phase AC output from the Inverters is connected to the Transformer Primary through Underground Armoured Cables. These cables are Copper or Aluminium XLPE insulated, Gl armoured, UV stabilised PVC ST2.

The Three Phase AC output from the Tranformer Secondary is connected to the RMU/Switchyard through Armoured Cables. These cables are Copper or Aluminium XLPE insulated, Gl armoured, UV stabilised PVC ST2.

Three Phase AC connection from the RMU is connected to the Switchyard through Armoured Cables. These cables are Copper or Aluminium XLPE insulated, Gl armoured, UV stabilised PVC ST2.